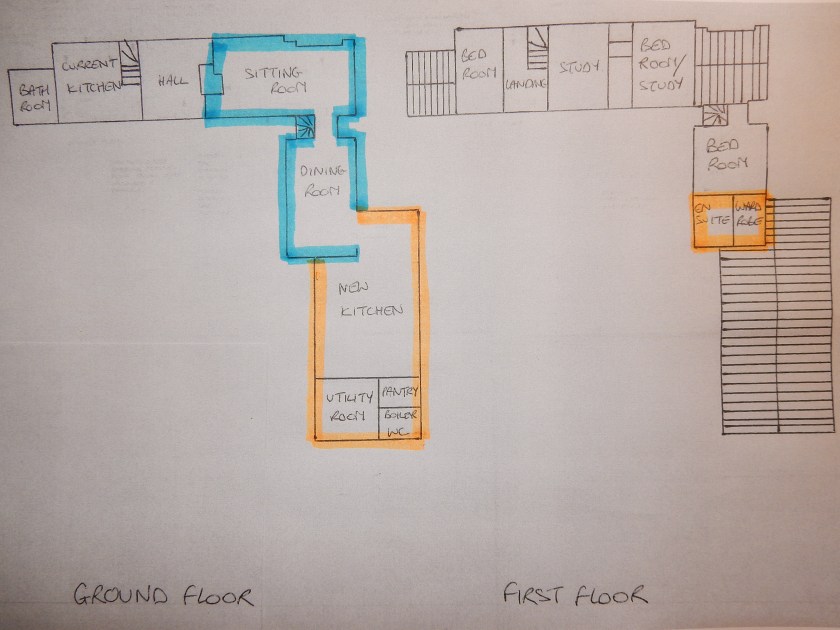

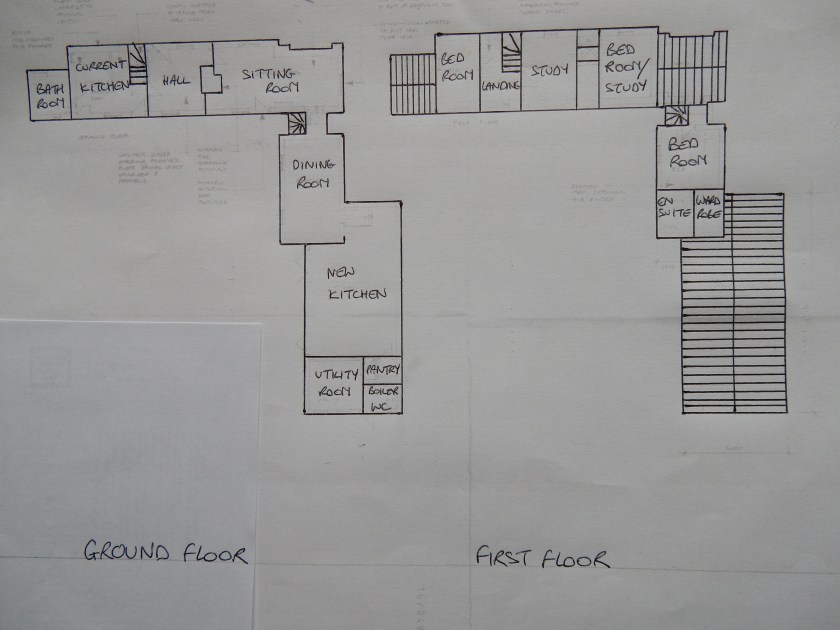

More than a year after the builders arrived on site to build our new extension we are almost finished. Years in the planning I really thought it would be done by Christmas – last Christmas. Little did I know that it would take more than twice as long to get to a place where we have a functioning kitchen and utility room.

On day one the garage block disappeared and the footings and foundations went up very shortly afterwards in one of the hottest summers on record. All looked good.

The first real hitch was the roof height, we needed to increase it by 300mm to ensure the tiles were at the right angle to stop the rain getting in. A key function for a roof! As we are Grade II listed and in a conservation area we had to go back through the planning process delaying us by almost four months.

This fed into our second challenge, pouring our concrete floor in a wet December. It took two months longer than planned to dry out sufficiently for it to be finished and polished.

The third big hold up has been the kitchen. The units were installed in April but the finish on the cupboard doors was wrong. They were also having trouble turning into worktops the wooden rafters we had rescued from the garages and were keen to reuse. Andy from The Plywood Kitchen Company, who also trade as 3rdedition, had the great idea of sealing all the woodworm, nail holes and joins with black resin then sanding it down to reveal some of the wood before finishing it with oil. It looked stunning but took ages to complete each stage. As a result they only came back to fit the doors and worktop in July, immediately after our return from two weeks holiday and only a couple of days before we were hosting M’s family for lunch!

Until the kitchen guys had done their bit we couldn’t connect up the gas that had taken so long to move from one side of the house to the other or get the sink and dishwasher plumbed in. Thankfully our heating engineer came out to connect the gas hob while they were still fitting the kitchen. However, our plumber suddenly wasn’t available and didn’t answer my calls. It turned out he had a bit of a meltdown with too much work and loads of problems with his own house. So we’ve had no water to the kitchen.

Thankfully the utility room was finished before we went away complete with sink and working tap and drainage. The dishwasher in our old kitchen was still connected so between the three spaces – the new kitchen, old kitchen and utility room we had a great lunch with M’s family showing off all the work we’d had done and our new kitchen space.

Last week our plumber returned and we now have a fully operational kitchen. There’s still the inevitable snagging including a draw beneath the sink that doesn’t fit now because of the pipework and the skirting board yet to install. However, we have really enjoyed moving into the new kitchen and unpacking boxes of glasses, crockery and kitchenware we haven’t seen for a long time. To complement this excitement we have invested in some new cutlery which we were able to get with a gift token I received as a leaving present from work.

The end result is stunning and a great example of co-creation with our kitchen people who turned our ideas into reality. M can’t wait to stop work and spend all his time in there creating wonderful meals although that won’t help my diet!

There are still two small rooms that need to be finished – the shelving in the pantry and the toilet and hand basin to be fitted in the downstairs cloakroom. Like all the tail ends to this, or any, project it’s a question of the time consuming process of chasing and trying to pin down people to come and do their stuff.

We also need to get the garden back in shape. The first step was to set out the hard landscaping and particularly the decking. After some extensive research we went for Accoya. It is a soft wood sustainably sourced which is treated with a process called acetylation which gives it the qualities of a hard wood by changing the cell structure. This means it will last and is guaranteed for 50 years which will see us out!

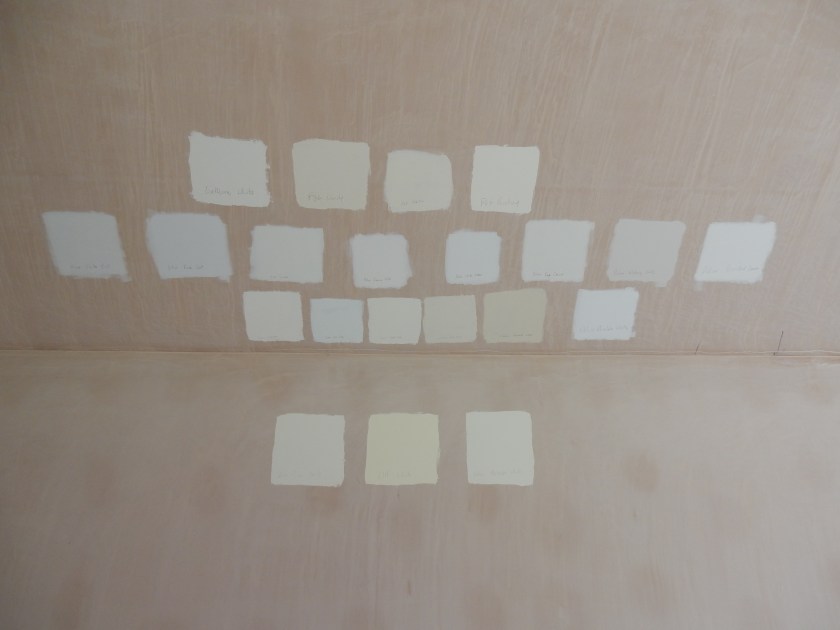

So it’s all looking good and time to relax and enjoy the space. Well, not yet, as we decided to keep going and start the renovation of the old house. A very different type of project and the start of another story.